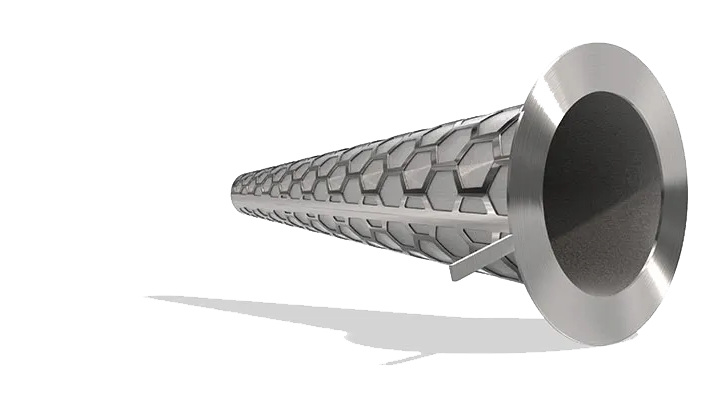

The widest range of conical strainers: from Witches Hat strainers to cone type.

This simple strainer design is commonly used in pipeline systems.

The mesh cone shape offers a large filtration area for catching pipe debris. This prevents damage to pumps, control valves, gauges, flow meters and any other process equipment.

Temporary conical strainers are compact, highly durable and easy to clean.

A Vee Bee Conical Strainer is therefore a low-cost solution in protecting process equipment against contamination during start-up and commissioning.

Different configurations can be manufactured to meet specific operational processes: including size, length, filtration level and identification marks.

Full support is also available.

Typical specifications

- Sizes: 0.5″ (15mm) to 30″+ (750mm+)

- Various S/S, Monel, Duplex, Carbon

- Maximum pressure rating class 2500lb+ (172 BarG+)

High Pressure

- Sizes: 0.5″ (15mm) to 30″+ (750mm+)

- Various S/S, Monel, Duplex, Carbon

- Maximum pressure rating class 2500lb+ (172 BarG+)

Witches Hat Strainer

- Sizes: 0.5″ (15mm) to 30″+ (750mm+)

- Various S/S, Monel, Duplex, Carbon

- Maximum pressure rating class 2500lb+ (172 BarG+)

Wedge Wire

- Sizes: 0.5″ (15mm) to 30″+ (750mm+)

- Various S/S, Monel, Duplex, Carbon

- Maximum pressure rating class 2500lb+ (172 BarG+)

Contact Us

How can we help?

Vee Bee Filtration UK Ltd

Unit D5 Coombswood Business Park Coombswood Way, Halesowen, West Midlands , B62 8BH The NetherlandsTel: +44 1384 378 884