Configurations

The following configurations of Tee Type strainer are available:

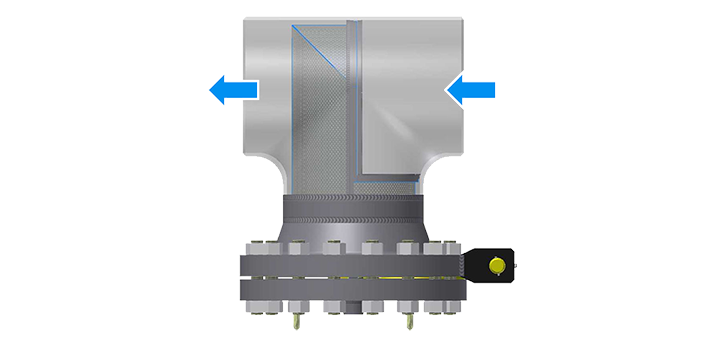

Type-A: Straight flow

- Used for straight flow only

- Most optimized Tee-type strainer design for pressure drop

- Sealing occurs at guiderails which may allow light bypass - this design is therefore suitable for coarser filtration only.

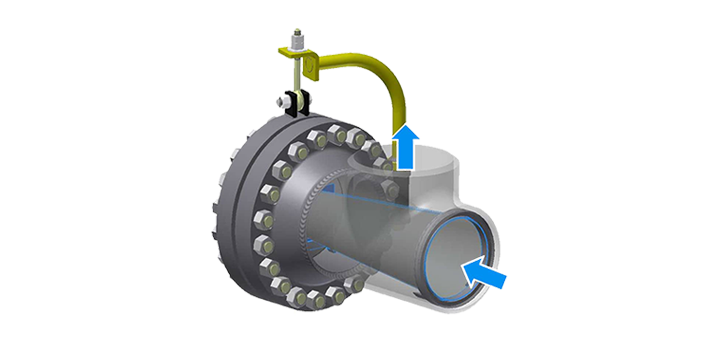

Type-B: Right angled flow

- Facilitates change in direction of flow at right angle.

- Inherently stronger construction compared to Type-C angle strainer because of its “internal pressure” configuration owing to its flow direction.

- Pressure drop is generally between Type-A and Type-C strainer.

- Positive seals at flat surfaces of the seating and element rings – this design is therefore suitable for fine filtration.

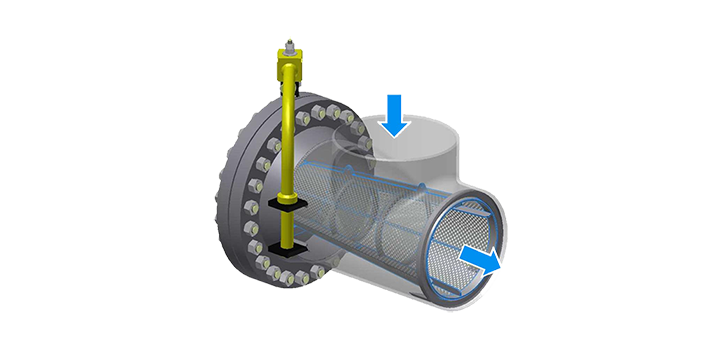

Type-C: Right angled flow

- Facilitates change in direction of flow at right angle.

- Requires internal reinforcement due to “external pressure” configuration owing to its flow direction.

- Pressure drop is generally higher than both Type-A and Type-B strainers.

- Positive seals at flat surfaces of the seating and element rings – this design is therefore suitable for fine filtration.

Contact Us

How can we help?

Vee Bee Filtration UK Ltd

Unit D5 Coombswood Business Park Coombswood Way, Halesowen, West Midlands , B62 8BH United KingdomTel: +44 1384 378 884